A large port undertakes a large number of loading and unloading tasks for pulverized coal and ore powder. Among them, the belt of the ship unloader serves as a key transportation channel for transferring goods from ships to the port's storage area. Real-time and accurate monitoring of its material level is of crucial importance. In the past, the port relied on manual periodic inspections to observe the belt's material level. This method is not only inefficient but also unable to detect abnormal belt material levels in a timely manner. For example, excessive material accumulation may lead to belt overload and tearing, while too little material will reduce loading and unloading efficiency. To improve the port's operational efficiency and ensure the safe and stable operation of equipment, the port has decided to introduce an advanced real-time monitoring system for the material level of ship unloader belts.

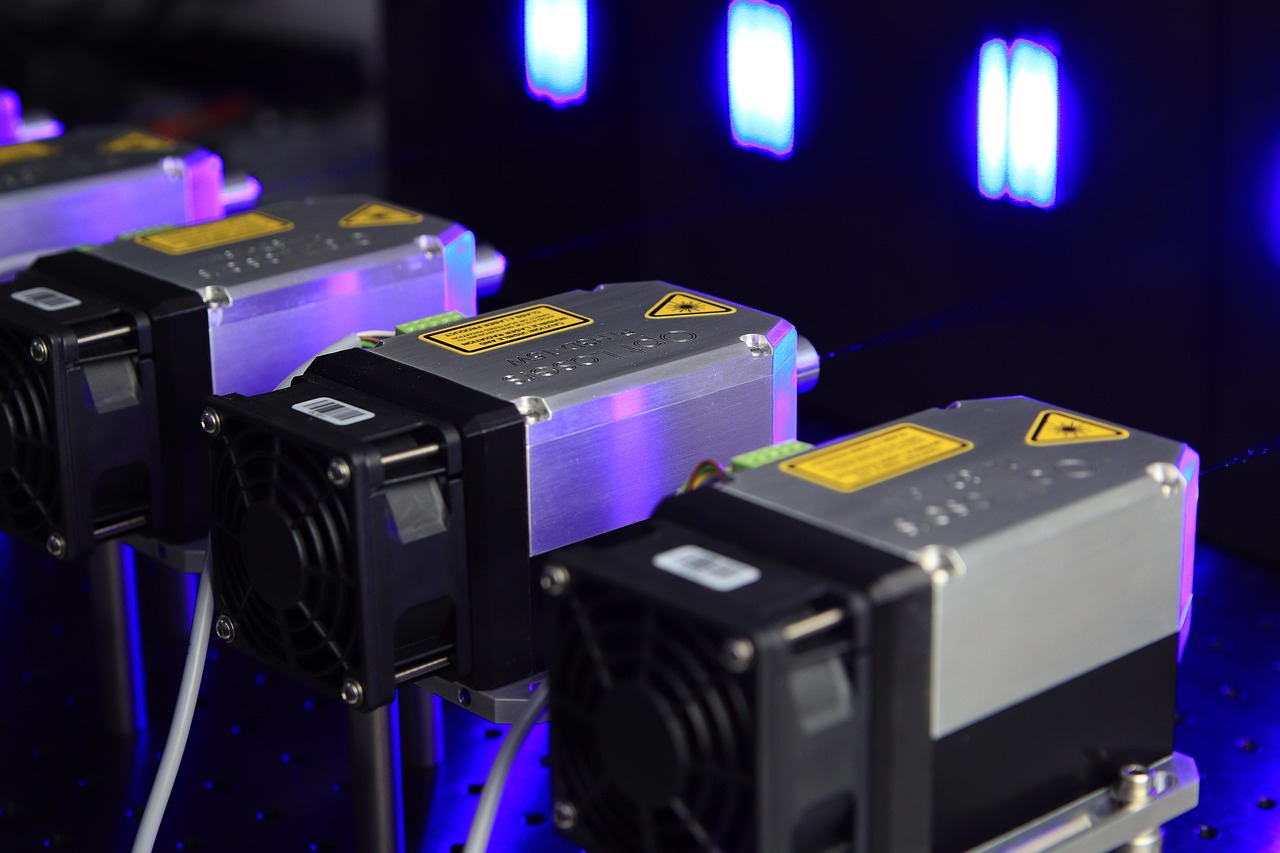

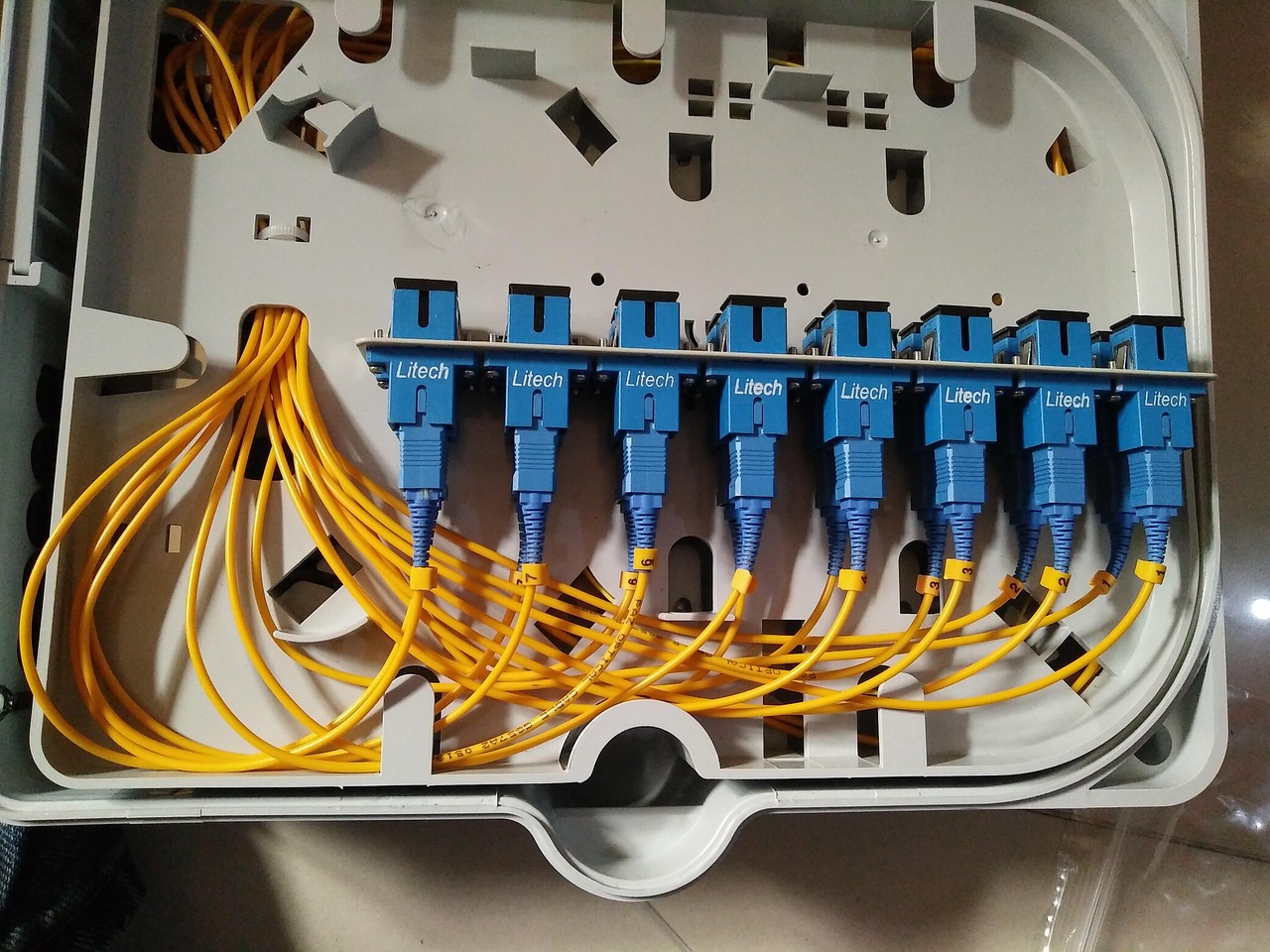

The solution selects dust-proof, moisture-proof, corrosion-resistant and vibration-resistant lidars and high-definition cameras with protective designs. It builds a real-time monitoring network through 5G communication and edge computing, and develops an intelligent data analysis system using big data analytics and artificial intelligence to achieve precise real-time monitoring and efficient management of the material level on the belts of port ship unloaders.

We will continue to focus on new technologies, optimize and upgrade existing monitoring systems to improve performance, expand the application scope of the system to other belt transportation equipment in the port, and integrate it with logistics and equipment maintenance systems. At the same time, we will strengthen cooperation with all parties in the industry to jointly promote the development of belt level monitoring technology in the port, and help the port upgrade intelligently and enhance its international competitiveness.